Technology in the construction and real estate industry has continuously transformed how inspection is carried out as building inspections shift from traditional methods. However, the use of traditional approaches also has some drawbacks, such as inefficiency, resource availability, and the chances of a higher error margin. Clearly, with the emergence of advanced technologies like drones, thermal imaging, and other recent innovative tools, the arena of building inspections has undergone incredible.

Using Thermal Imaging for Building Inspection

Thermal imaging has developed into a highly effective technique in modern building inspection for determining hidden problems and achieving safe structures.

Detecting Thermal Features

Thermal cameras can identify moisture inside building materials by showing local areas that are colder due to wet areas. This may raise the possibility of early leakage detection, water damage, and mould growth before the structural damage happens or the air quality indoors is affected.

Electrical System Assessment

Thermal imaging is useful in the examination of electrical units, finding defective components (e.g. noisy wiring, electrical connection, or equipment), and eliminating fire risks. As early detection of electrical anomalies prevents any equipment failure electrical safety would be guaranteed..

Advantages of Thermal Imaging in Building Inspection

Unlike invasive procedures that necessitate physical access or any structural changes, thermal imaging is non-destructive. The experts can look at buildings without causing any interruption or damage that may lead to Normal Inspections and preventive maintenance.

Comprehensive Data Collection

Thermal cameras yield high-resolution infrared images and temperature readings that are comprehensive and available for data analysis and decision-making processes. This data allows maintenance managers to prioritize tasks, distribute resources effectively, and track progress along the way.

Early Problem Detection

Imaging thermal anomalies cause the early detection of problems that can be addressed quickly through repair and corrective actions. Adopting such a proactive approach will therefore reduce downtime, prevent expensive repairs, and protect assets.

Safety and Risk Mitigation

The thermal images can greatly reduce the associated risks by removing the burden of any manual operations. For instance, the safety of workers can be guaranteed since they will not have to be exposed to situations that jeopardise their lives. Also, the thermal images aid in identifying and fixing structural deficiencies, moisture-related problems, and electrical hazards.

Regulatory Compliance

Thermal imaging helps regulators monitor code violations, safety hazards, and environmental concerns, enhancing compliance. Thermal inspection audits satisfy industry standards, insure needs, and legal liabilities.

Role of Robots in Structural Evaluation

Robotics has become an integral part of the modern building inspection arena, having introduced a host of advantages ranging from efficiency, safety, accuracy, and data gathering.

Enhanced Security and Less Danger

Human inspectors can reduce the risk of entry into hazardous environments or perform tasks that are challenging or risky, such as climbing at heights, managing dangerous materials, or venturing into enclosed locations by using robotics. Due to this, the risk of accidents and injuries to workers is diminished. Robotics systems can be piloted from a distance which allows for hazardous inspections to take place from a safe environment. Remotetary operation increases safety while keeping the real-time control and inspection processes under monitor.

Efficient Data Gathering and Processing

Robotics fit with the most advanced cameras, sensors, LiDAR as well as thermal Imaging and multispectral captures detailed data during the inspections. This visual data includes surface imagery, 3D modelling, thermal mapping, point cloud visualization, and environmental parameters, which give you a complete picture of building conditions. The integration of robotics and AI algorithms enables one to do tasks such as data analysis, anomaly detection, and defect recognition automatically. AI-based software processes giant datasets at large finds patterns, forecasts equipment failures, and generates meaningful reports, which enable decision-making and make it easier and faster.

Structural Assessment and Monitoring

Robotics can serve as a tool to test structural components which can include beams, columns, walls, and foundations for indications of corrosion, cracks, distortion, or deterioration. They are involved in the evaluation of buildings as far as static condition, locating weaknesses, and classifying maintenance and repair interventions. Certain robots featuring 24/7 monitoring capabilities are capable of data collection in real-time, trend analysis, as well as performance monitoring. Through this preventive action, structural damages will be timely identified, failures will be avoided, and asset life will be prolonged.

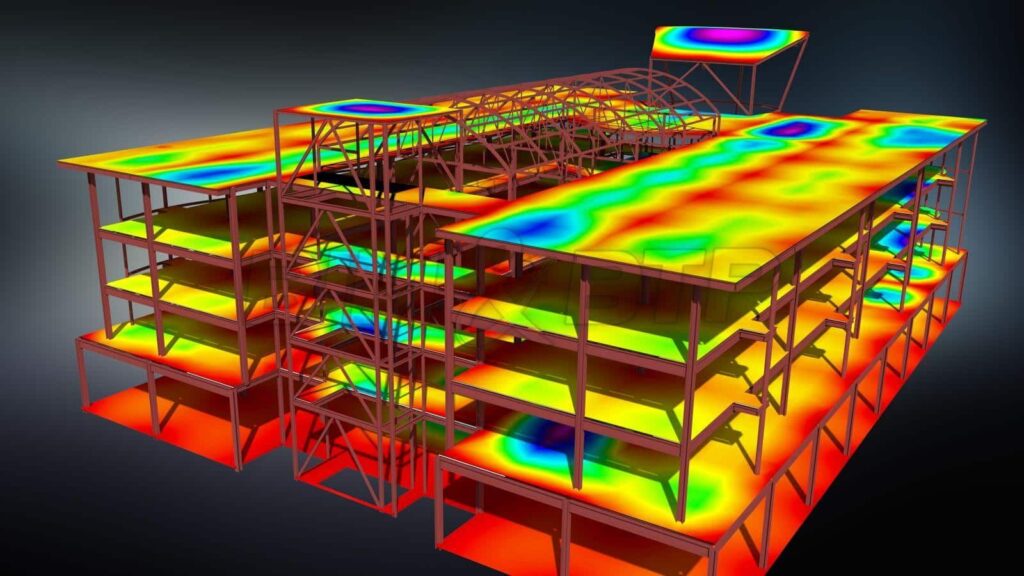

Compatibility with the Building Information Modeling system (BIM)

Though robotics is a digital twin creator, it is capable of as-built reality data, geometric measurements, and asset attribute capture. BIM platforms that combine robotics inspection data with the digital twin of buildings operating during asset management, and maintenance planning become possible with this. Digital twins provide virtualization of buildings that help in lifecycle management, where in this case historical inspection data, maintenance records, and performance metrics are connected to a unified platform. This approach, thus, promotes openness and transparency on the level of asset management, offers decision support, and facilitates business operations.

Building Inspection Techniques

Building inspection methodology includes an array of means and technologies aimed at getting comprehensive evaluation, safety, and performance of buildings and structures. These are the main inspecting methods that are used nowadays to evaluate the structures.

High-frequency sound waves in the Assessment of Structures

UT makes use of sound waves that have a high frequency as a means of finding flaws, measuring the thickness of various materials, and knowing their structural properties in steel, concrete composites, and other materials.

Radiographic Testing (RT)

Radioactive ionizing radiations in the form of either X-rays or gamma rays can be employed to inspect the welded joints, internal structures, and any hidden defects either discontinuity or foreign objects present.

Finding Risks in Ferromagnetic Substances

MPT is a technique responsible for the nearby surface and depth flaws in ferromagnetic materials (for example, steel) by applying magnetic fields at these locations and detecting them as the particles accumulate in these areas.

Thermographic Inspection

Thermographic inspection through thermal imaging cameras it possible to detect hotspots and cold spots, openings in the building envelope, damages in the wiring, and variances in air temperature, by buildings.

Structural Analysis and Testing

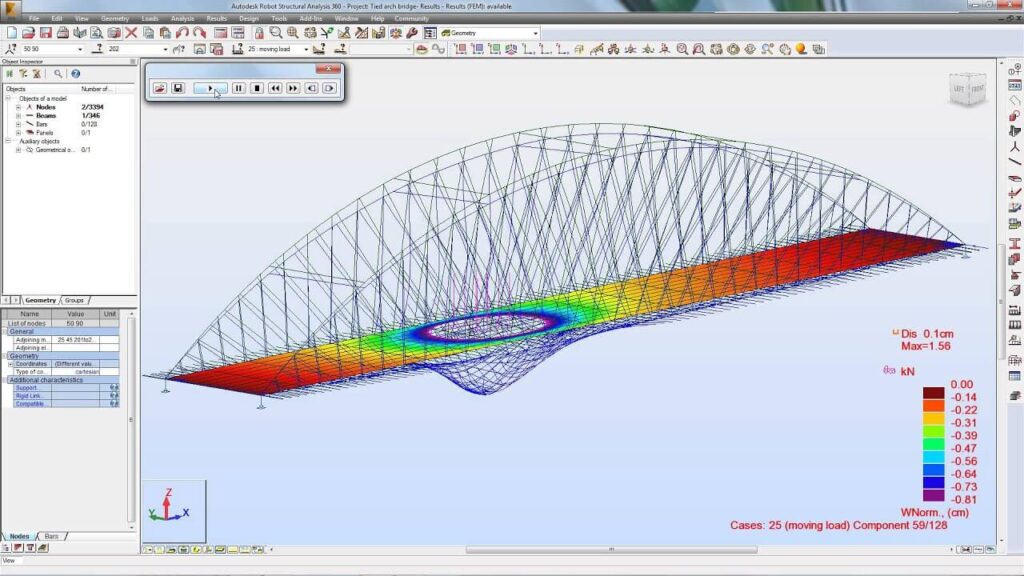

Tensile analysis, beam analysis, and other structural analysis techniques define the ability of structures and the way they hold their shape and ensure their stability. These techniques include:

Load Testing

The process of load testing involves sending a controlled load (e.g., the beams, columns, slabs) which is necessary to estimate, and monitor stresses, and the performance of the structural elements under the simulated conditions.

Vibration Analysis

Vibration analysis is used for dynamic behaviour assessment, natural frequencies and modes, and resonance or damping attributes, and this all helps in structural stability and comfort analysis and contributes to the vibration-related problems understanding.

Benefits of Drone Inspections

Drones provide many advantages over inspection platforms for different sectors including construction, real estate, infrastructure maintenance, farming, and environmental monitoring. In the following, I enumerate the most important benefits that the usage of drones for inspections has.

Improved Safety

Drones-based inspections will reduce the requirement of human inspectors to handle dangerous or seemingly inaccessible situations, which will decrease the chance of accidents and injuries. They can navigate through tight spaces and towering structures, as well as assess areas with possible dangers without endangering employees, using their ultra-mobile platforms.

Cost-Effectiveness

Unlike the conventional inspections that demand, in most cases, expensive devices, human resources, and sometimes arrangements like scaffolding or aerial lifts, drone inspection is in the guideline of being more cost-effective. They run labour costs, industrial equipment, and incidental downtime down so that businesses can make cost-saving.

Time Efficiency

In less than an hour, personal drones can produce high-resolution images and videos of vast areas or large structures that are impossible for the human eye to achieve. This efficiency ensures the quick performance of inspection, thereby fastening data gathering, analyzing, and making of a key decision. It has another advantage of giving inspectors more time to identify safety issues without interrupting ongoing processes.

Access to Inaccessible Areas

Drones can reach places that it is tough for humans to approach like tops of the buildings, high buildings, bridges, pipelines, and hilly locations. This makes sure that background and hard-to-reach parts of the structure or asset items are properly inspected including the ones that degrade easily, corrode, or have signs of damage.

High-Quality Data

Drones are nowadays the competent cameras, sensors, and imaging devices (including thermal imaging and multispectral cameras) that take detailed and verify data. Such intelligence comprises visual imagery, infrared imagery, 3D models, and topographical data, from which one can make a full picture of the shape and work efficiency of the assets.

Early Detection of Issues

Through routine drone inspections, the possibility of natural signs of the existence of flaws or defects in the early stage is significantly increased. Such early issue detection permits rapid implementation of the appropriate maintenance, repair, or corrective actions designed to stop the escalation of a minor deficiency into either failure at a major level or until it becomes a personal safety issue.

Conclusion

Utilizing technology, the area of structured management is subject to constant changes, providing an extensible system of data gathering, analysis, and decision-making. Adopting the new technologies represents somewhat a great improvement in the accuracy and efficiency of the inspections. It also contributes to the environment that is robust, safe, and sustainable. In the future, we will certainly witness a harmony between technology implementation and Modern Building Inspection to deliver creativity and success in the construction industry.